Description

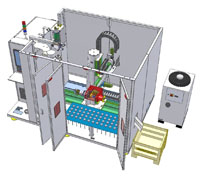

Automatic powder PTA welding equipment managed by C.N. including piece loading and unloading system for all types of plungers for the glass industry such as Blow-Blow, Press-Blow, NNPB.

Features

ROBO NEXT P consists of a work station mounted on a platform and locked inside a safety cell and which includes:

• Handling with five axes system, 3 Cartesian and two rotating ones for handling and picking up the piece

• PTA Inverter 200A generator, YZR 250 torch with special nozzle and standard AP power feeder

• Pick-up warehouse with relative loading tray where up to 52 plungers can be housed

• Numerical Control MITSUBISHI with programming in ISO language

It is an innovative handling system that for the first time combines the metallurgical characteristics of the welded deposit with the Plasma Transferred Arc process to the glass plungers industry. The PTA powder process also allows to deposit in addition to the classic Nickel or Ni + carbide base powders also the Cobalt base powders (Stellites) which guarantee performances lasting up to 4 times longer than traditional processes.

The ROBO NEXT series also includes a MANUAL version which is not equipped with workpiece loading and unloading but requires an operator.