Description

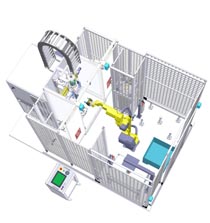

PTA200ROT HR is an automatic equipment for P.T.A. powder hardfacing with integrated management of the parameters of welding and motion; the machine is suitable for rings and small workpieces of cylindrical and round shape. The welding system is integrated by a pre-heating induction 6 KW and by a Manipulator for the fully automatic charge/descharge cycle.

Working cycle: The welding pieces are detected by a camera and then collected from a tray on a multi-pallet and positioned between the coils of the induction heater; the temperature is measured by an optical pyrometer. The hot piece is collected by the robot and positioned on the PTA 200 ROT for welding: in the meanwhile another piece can be collected from tray and positioned on the pre-heater. When welding is finished the manipulator catches the piece and deposits on an apposite container, re-starting another working cycle.

The multi-pallet system with piece presence sensors and a load cell positioned near the base of the powder feeder allow the welding of pieces in fully automatic cycle EVEN WITHOUT THE PRESENCE OF ANY OPERATOR, giving a variable autonomy of 6-8 hours.

Features

PTA200ROT welding machine is basically formed by:

• welding machine PTA200i complete of torch 250A and standard powder feeder

• oscillator with adjustable torch holding device, stroke mm. 100

• rotating table, max load kg 10

• control panel with PLC Mitsubishi